A motto of KOAGAS NIHON Group is for every employee to fulfill the individual responsibility with the high consciousness of the safety and environmental protection.

It can be said that the LP Gas cylinder filling process by way of the blow by-pass system was developed under such circumstances of the KOAGAS NIHON Group.

Since the first unit was installed at the Sendai Factory in 1956, all the units including the licensed ones have been successfully on stream.

The process was licensed to the overseas company.

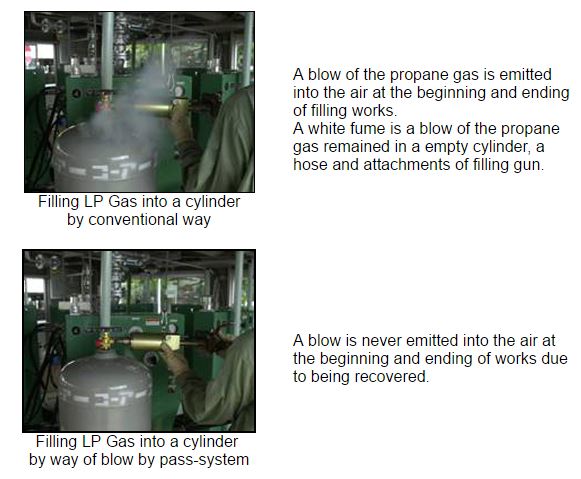

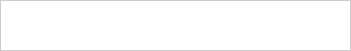

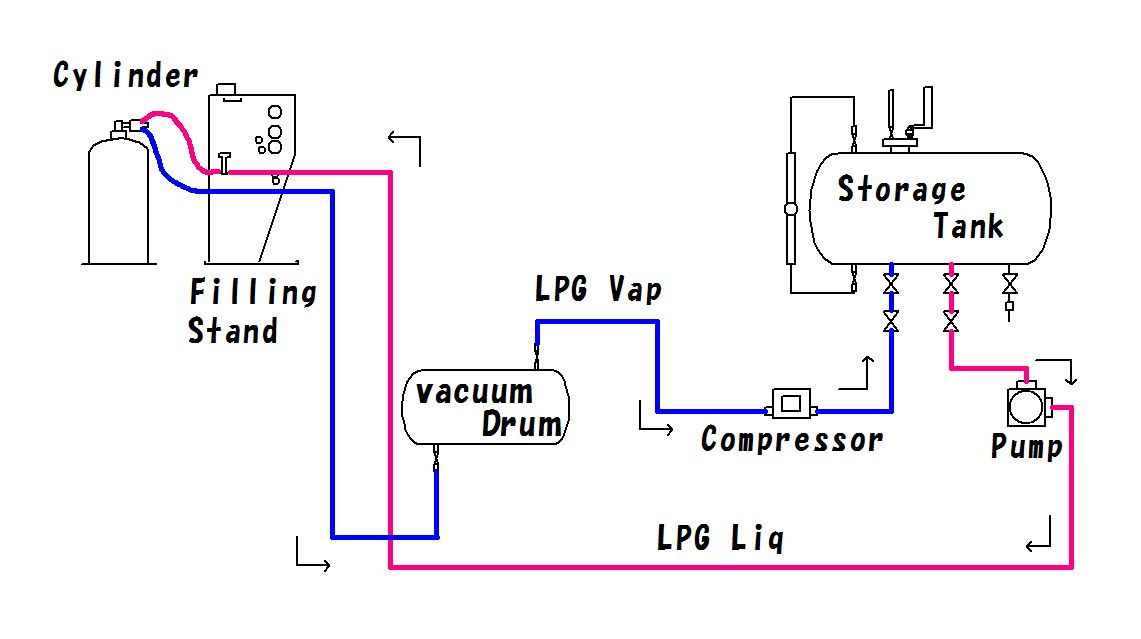

As shown in the process flow sheet below, the process is quite innovative in terms of the fact that the works of filling LP Gas into a cylinder can be done under the safe and clean conditions since a blow of propane gas is perfectly recovered as the product of LP Gas without being emitted into the atmosphere.

The process can contribute to a great extent to not only the improvement of the working circumstances but also the protection of the unit from any fire or accident by explosion etc.

The unit consists of the filling hoses with a uniquely designed three-way-rotary valve and the attachments, control boxes and the equipments for the recovery of the blow of the propane gas, etc.

The process can protect not only the blow of the propane gas from emitting into the atmosphere but also can shorten remarkably the filling time, can protect the LP Gas from over-filling and can use for recovery of residual LP Gas remaining in a storage tank.

Flow Sheet of Blow By-pass System

Filling section